Sterilecontainer systems

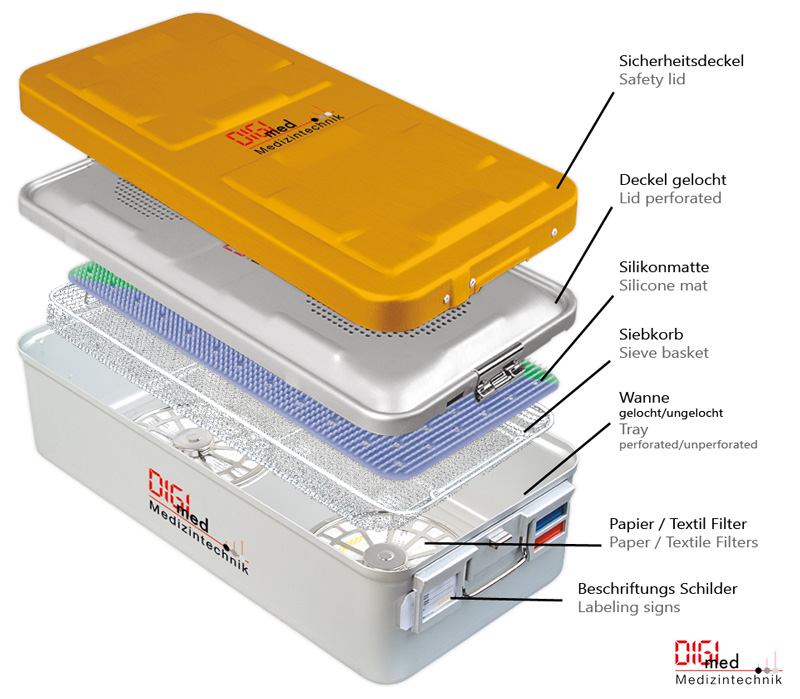

The product range of sterile containers includes the systems 1/1, 1/2, 3/4, Minicontainer, Dentalcontainer in the available colors of the lids from silver, blue, red, money (gold), green to black as perforated variant with filter or unperforated. A wide range of sieve baskets, silicone mats, identification labels and other accessories for sterilization processing complete the product range.

Sterile container

1/1 Container (580x280 mm / basic model)

1/2 Container (285x280 mm)

3/4 Container (465x280 mm)

Container (300x138x65)

Container (500x155x75)

Large-Container (600x400 mm)

Mini-Container (300x140 mm)

Dental-Container (310x190 mm)

Optics Container (250x60x50)

Optics Container (450x70x70)

Accessories such as filters and identification labels

Informations / Products

Disposal container, steel container, barrier, Teflon filter. Safety model, safety lids, colors, perforated bottoms, perforated trays, perforated and non-perforated lids. Sterile containers for sterilization of medical and veterinary instruments and implants.

Safety closure as well as colored identification labels available for the anodized aluminum containers. Brush dispensers, indicator labels, closure seals, sterile goods, sterile containers with paper filters, textile filters, sieve baskets are available as supplements.

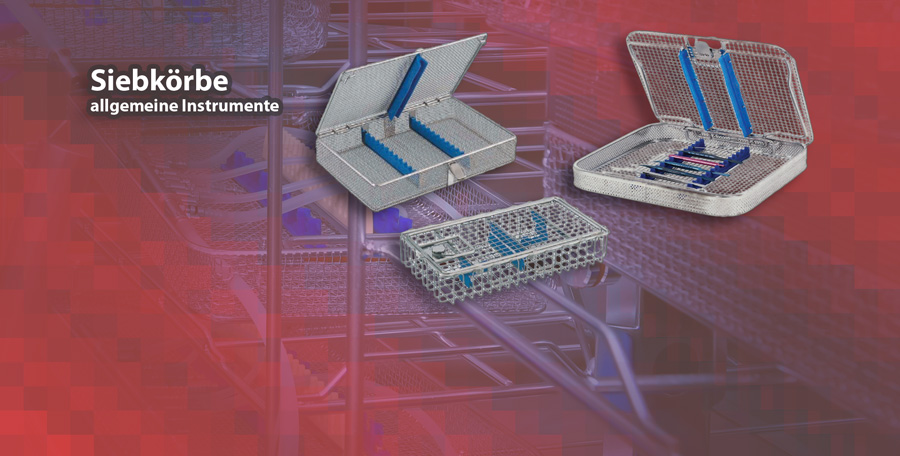

Silicone holder and Seeve Basket

Stainless steel strainer baskets with silicone holder for medical and dental instruments.

The silicone holders can be used flexibly thanks to screw connection.The durable polymer base for an ideal hold with or without lid. The screen baskets are stackable for easy transport.

Company

We have specialized in the production of Sterile containers and sieve baskets .

The coloring of the container lids and safety lids makes it impossible to mix up the sterilized items. Almost all container bottoms models are perforated and come with sterilization filter or unperforated with sieve basket or silicone mat or insert cloths in blue / green.

Due to the constantly growing demands on the market, our sterile container portfolio is constantly being expanded. Through our webshop / online store we would like to be present in the field of medical supplies / practice supplies in the future.

Web page

Certificates

Download area

Instruction manuals

Sterile container filtration systems are an essential component in many industries, including pharmaceuticals, biotechnology and medical devices. These systems are designed to provide a sterile environment for the storage and transport of sensitive materials such as drugs, vaccines and medical devices.

The basic components of a sterile container filter system include a container, a filter and a closure. The container is usually made of a durable, lightweight material, such as plastic, teflon or aluminium stainless steel, and is designed to hold the material to be filtered. The filter is usually made of a porous material, such as a membrane or sintered metal, and is designed to remove contaminants from the material as it passes through the filter. The closure is usually a screw-on or snap-on cap that seals the container securely and prevents leakage. Common models on the market are paper and textile filters. However, we also offer models from Valve, Bio-Barrier or PTFE Teflon filters with fixed integration in the lid.

Sterile container filter systems are designed to meet strict quality and performance standards and are subject to rigorous testing and validation procedures. These systems are typically validated to ensure they meet sterilization, filtration and material compatibility requirements and are designed to provide a high level of protection against contamination and degradation of stored or transported material.

In addition to providing a sterile environment for sensitive materials, sterile container filtration systems also offer several other benefits, including improved product quality, increased efficiency and reduced costs. By providing a controlled environment for the storage and transport of sensitive materials, these systems can help ensure that materials remain safe, effective and of high quality throughout their lifecycle.

In summary, sterile container filtration systems not only for surgical Instruments are an essential component in many industries and play a critical role in ensuring the safety and quality of sensitive materials. Whether you are a manufacturer, distributor or user of these systems, it is important to understand the benefits and requirements of these systems and select a system that meets your specific needs and requirements.

Sterile container filtration systems are an essential component in many industries, including pharmaceuticals, biotechnology and medical devices. These systems are designed to provide a sterile environment for the storage and transport of sensitive materials such as drugs, vaccines and medical devices.

The basic components of a sterile container filter system include a container, a filter and a closure. The container is usually made of a durable, lightweight material, such as plastic, teflon or aluminium stainless steel, and is designed to hold the material to be filtered. The filter is usually made of a porous material, such as a membrane or sintered metal, and is designed to remove contaminants from the material as it passes through the filter. The closure is usually a screw-on or snap-on cap that seals the container securely and prevents leakage. Common models on the market are paper and textile filters. However, we also offer models from Valve, Bio-Barrier or PTFE Teflon filters with fixed integration in the lid.

Sterile container filter systems are designed to meet strict quality and performance standards and are subject to rigorous testing and validation procedures. These systems are typically validated to ensure they meet sterilization, filtration and material compatibility requirements and are designed to provide a high level of protection against contamination and degradation of stored or transported material.

In addition to providing a sterile environment for sensitive materials, sterile container filtration systems also offer several other benefits, including improved product quality, increased efficiency and reduced costs. By providing a controlled environment for the storage and transport of sensitive materials, these systems can help ensure that materials remain safe, effective and of high quality throughout their lifecycle.

In summary, sterile container filtration systems not only for surgical Instruments are an essential component in many industries and play a critical role in ensuring the safety and quality of sensitive materials. Whether you are a manufacturer, distributor or user of these systems, it is important to understand the benefits and requirements of these systems and select a system that meets your specific needs and requirements.

instruments sterile goods suitable Landing pages for sterile container-systems

implantate-hersteller.de | instrumente-chirurgisch.de | instrumente-dental.de | medizintechnik-instrumente.de | mikrochirurgische-instrumente.de | atraumatische-instrumente.de | augenchirurgische-instrumente.de | hno-instrumente.de | veterinär-instrumente.de

Contact / Approach

Digimed Medizintechnik

Kreutzerstrasse 1

D-78573 Wurmlingen Germany

Tel. +49(0)7461-9101172

Fax. +49(0)7461-9101261

Webseite: digi-med.de | orthopedics-implants.com

e-Mail: info@digi-med.de

Sozial Media: Twitter | LinkedIn | Xing | Skype